Optimizing Power: Effective Battery Maintenance Strategies

Empowering Efficiency: Unveiling Battery Maintenance Strategies

Effective battery maintenance is essential for ensuring optimal performance and prolonging the lifespan of your power storage systems. Explore key strategies to implement for efficient battery management and dependable power supply.

Battery Maintenance Strategies: A Comprehensive Guide

For a deeper exploration of battery maintenance strategies, refer to “Battery Maintenance Strategies.” This comprehensive guide provides insights, case studies, and resources to help you navigate the intricacies of maintaining batteries for reliable power storage. Visit Battery Maintenance Strategies for invaluable information.

Regular Inspections and Cleaning

Initiate a proactive approach to battery maintenance by conducting regular inspections and cleaning. Check for signs of corrosion, loose connections, or any physical damage. Clean terminals and surrounding areas to prevent the accumulation of dirt and corrosive substances, which can compromise performance.

Optimizing Charging Practices

Implementing proper charging practices is crucial for battery health. Avoid deep discharges and overcharging, as they can lead to accelerated wear. Follow manufacturer recommendations for charging voltages and currents. Invest in smart chargers that adjust charging parameters based on battery condition, enhancing efficiency.

Temperature Control Measures

Batteries are sensitive to temperature fluctuations. Implement measures to control the temperature of battery storage areas. Extreme temperatures, both hot and cold, can affect performance and lead to premature aging. Insulate battery enclosures, provide ventilation, and consider climate control solutions for optimal temperature regulation.

Scheduled Capacity Testing

Regularly conduct capacity testing to assess the performance of your batteries. Scheduled tests help identify any decline in capacity, enabling timely intervention or replacement. This proactive approach ensures that your batteries can meet the required power demands and operate at peak efficiency.

Watering and Electrolyte Levels Management

For flooded lead-acid batteries, monitoring and managing electrolyte levels is essential. Check water levels regularly and top up with distilled water as needed. Maintaining the correct

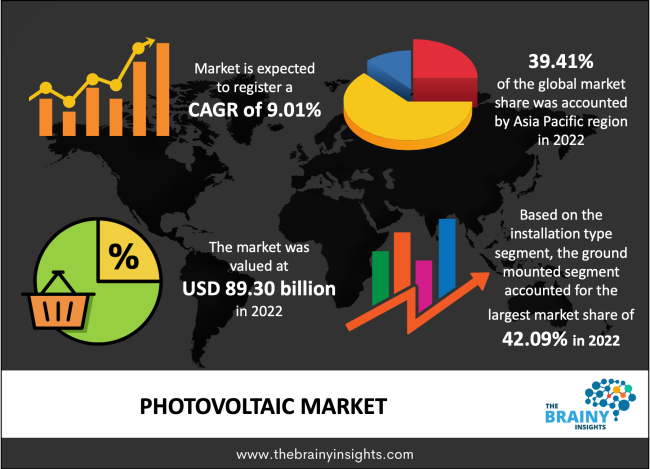

Insights into Ground Mount Installation Techniques

Insights into Ground Mount Installation Techniques

In the realm of renewable energy, ground mount installations are gaining prominence for their efficiency and versatility. This article delves into the key insights that make ground mount installations a compelling choice for harnessing solar power.

Optimal Site Selection for Ground Mount Installations

Choosing the right site is paramount for the success of ground mount installations. Factors such as sunlight exposure, topography, and proximity to existing infrastructure play crucial roles. Optimal site selection ensures maximum energy generation and long-term sustainability.

Advanced Foundation Systems for Stability

The stability of a ground mount solar array is dependent on its foundation. Innovative foundation systems, such as helical piles or ground screws, offer enhanced stability while minimizing environmental impact. These advanced systems streamline the installation process and provide a robust foundation for the solar array.

Tilt and Orientation for Maximum Energy Yield

Ground mount installations allow for flexibility in adjusting the tilt and orientation of solar panels. This adaptability optimizes energy yield by maximizing exposure to sunlight throughout the day and across seasons. Careful consideration of tilt angles and orientation significantly contributes to the overall efficiency of the solar array.

Integration of Tracking Systems for Enhanced Performance

To further boost energy production, some ground mount installations incorporate tracking systems. Single-axis and dual-axis trackers dynamically follow the sun’s path, ensuring panels are always oriented for optimal sunlight exposure. This integration enhances overall performance, especially in regions with variable sunlight conditions.

Efficient Wiring and Cable Management

The efficiency of a ground mount installation extends beyond the solar panels themselves. Thoughtful wiring and cable management contribute to the reliability and longevity of the system. Implementing efficient wiring practices minimizes energy loss and reduces the risk of potential issues over the operational lifespan of the solar array.

Environmental Considerations and Mitigation Strategies

Optimizing Operations: Inspection and Maintenance Guidelines

Ensuring Efficiency: Comprehensive Inspection and Maintenance Guidelines

Efficient operations are the backbone of any industry, and adhering to thorough inspection and maintenance guidelines is paramount. In this article, we delve into the essential aspects of inspection and maintenance processes, offering insights to optimize performance and prolong the lifespan of equipment and assets.

1. The Significance of Regular Inspections

Regular inspections form the cornerstone of effective maintenance strategies. This section highlights the importance of scheduled inspections to identify potential issues before they escalate. Routine checks allow for proactive interventions, reducing the likelihood of unexpected breakdowns and costly repairs.

2. Developing a Comprehensive Inspection Checklist

A comprehensive inspection checklist is a valuable tool for maintenance teams. This part explores the creation of detailed checklists tailored to specific equipment or assets. Checklists ensure that no crucial component is overlooked during inspections, contributing to a systematic and thorough assessment.

3. Prioritizing Preventive Maintenance

Preventive maintenance is a proactive approach to equipment care. This section emphasizes the significance of prioritizing preventive maintenance tasks based on criticality and potential impact on operations. Addressing issues before they lead to failures enhances reliability and minimizes downtime.

4. Embracing Predictive Maintenance Technologies

Advancements in technology have paved the way for predictive maintenance. This part discusses the integration of technologies like sensors and data analytics to predict equipment failures. Embracing predictive maintenance allows organizations to schedule interventions precisely when needed, optimizing resource utilization.

5. Training and Empowering Maintenance Teams

A knowledgeable and empowered maintenance team is essential for effective inspections and maintenance. This section explores the importance of continuous training to keep teams updated on industry best practices, new technologies, and safety protocols. Empowered teams contribute to a culture of excellence in maintenance.

6. Establishing a Routine Lubrication Schedule

Proper lubrication is a critical aspect of equipment maintenance. This part