Optimizing Operations: Inspection and Maintenance Tips

Efficient and reliable operations rely on a proactive approach to inspection and maintenance. In this article, we delve into valuable tips to optimize your processes, enhance equipment longevity, and ensure a smooth operational workflow.

The Importance of Regular Inspections

Regular inspections form the foundation of effective maintenance. Scheduled checks allow you to identify potential issues before they escalate, preventing costly breakdowns and unplanned downtime. Establish a systematic inspection schedule tailored to the specific needs and critical components of your equipment or infrastructure.

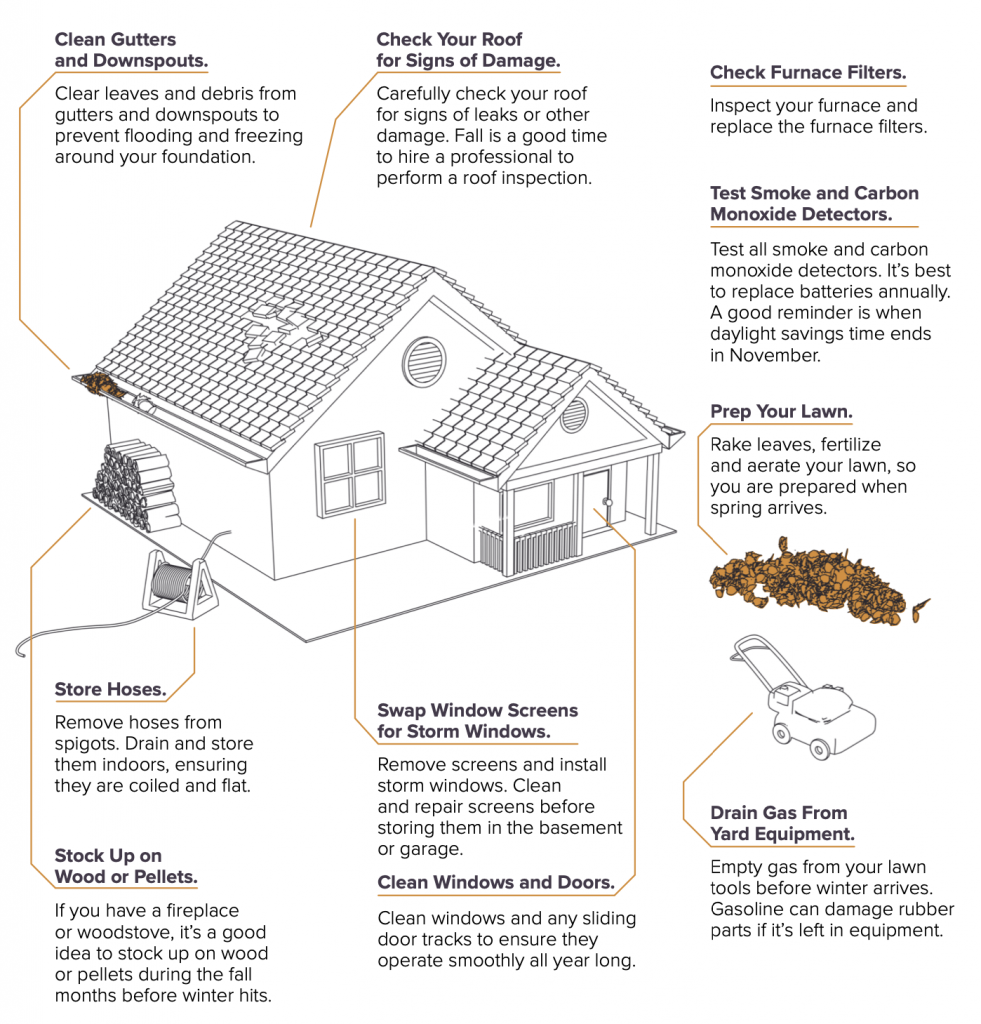

Comprehensive Inspection Checklists

Developing comprehensive inspection checklists is crucial for thorough evaluations. Create detailed lists that cover all critical aspects of the equipment or systems under examination. Include visual inspections, functional tests, and measurements to ensure a comprehensive assessment. Regularly update checklists based on equipment changes, industry standards, or lessons learned from past inspections.

Inspection and Maintenance Tips: Explore Further Insights

For additional insights and a comprehensive guide on inspection and maintenance, visit Inspection and Maintenance Tips. This resource provides detailed information and strategies to enhance your inspection processes and prolong the life of your assets.

Training and Qualifications for Inspectors

Ensure that personnel conducting inspections are well-trained and possess the necessary qualifications. Training programs should cover equipment knowledge, inspection procedures, safety protocols, and regulatory compliance. Well-trained inspectors contribute to accurate assessments and effective communication of findings.

Utilizing Technology for Inspections

Integrate technology into your inspection processes to enhance efficiency and accuracy. Mobile apps, sensors, and IoT devices can streamline data collection, automate routine inspections, and provide real-time insights. Embrace predictive maintenance technologies to anticipate potential issues and optimize maintenance scheduling.

Prioritizing Safety in Inspections

Safety should be a top priority during inspections. Establish clear safety protocols for inspectors, ensuring they use appropriate personal protective equipment (PPE) and follow industry safety standards. Prioritize the safety of both personnel and equipment during inspection activities.

Proactive Maintenance Strategies

Transition from reactive to proactive maintenance strategies. Proactive maintenance involves anticipating and addressing issues before they result in failures. Use data from inspections and historical performance to identify trends, allowing for predictive maintenance that minimizes downtime and extends equipment life.

Timely Repairs and Component Replacements

Address identified issues promptly through timely repairs and component replacements. Delays in addressing problems can lead to further damage and increased repair costs. Establish a streamlined process for initiating and completing necessary repairs, and keep an inventory of critical spare parts to minimize downtime.

Documentation and Record-Keeping

Maintain detailed documentation of inspection findings, maintenance activities, and repairs. Accurate record-keeping serves as a historical reference, enabling trend analysis and informed decision-making. Digital documentation systems can enhance accessibility and facilitate data analysis for continuous improvement.

Regular Audits and Performance Reviews

Conduct regular audits to assess the effectiveness of your inspection and maintenance programs. Evaluate key performance indicators, such as equipment reliability, downtime, and maintenance costs. Use the insights gained from audits to refine processes, implement improvements, and ensure ongoing optimization.

Collaboration and Communication

Foster collaboration and communication between inspection teams, maintenance personnel, and other relevant departments. Establish clear channels for reporting findings, initiating repairs, and sharing insights. Effective communication ensures a holistic approach to optimizing operations and facilitates a culture of continuous improvement.

Sustainable Operational Excellence

By implementing these inspection and maintenance tips, organizations can work towards sustainable operational excellence. Proactive approaches, technological integration, and a commitment to safety contribute to efficient operations, increased equipment reliability, and a foundation for long-term success.